Tundish Metering Nozzles

LONG KETER manufactures a comprehensive range of zirconia based TUNDISH METERING NOZZLE for continuous casting of steel.

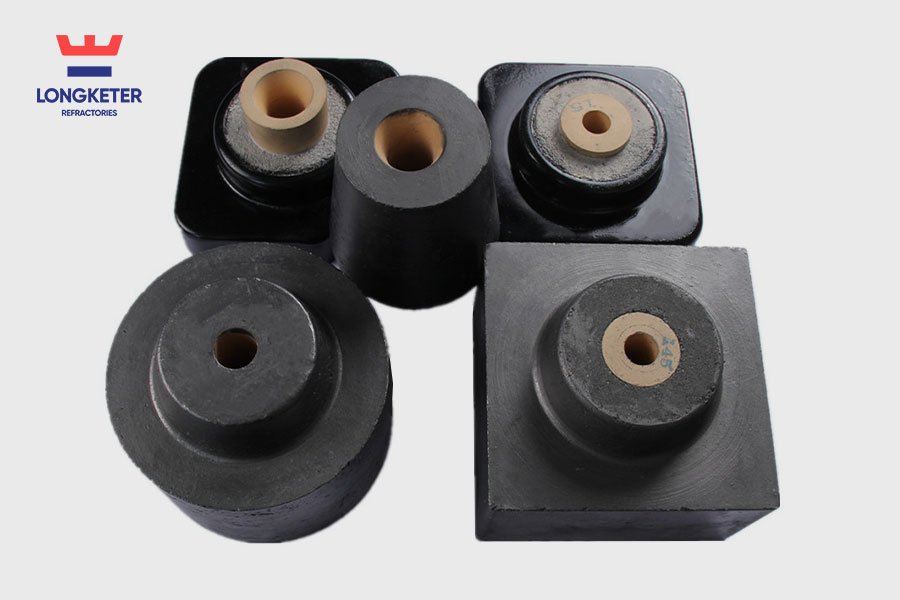

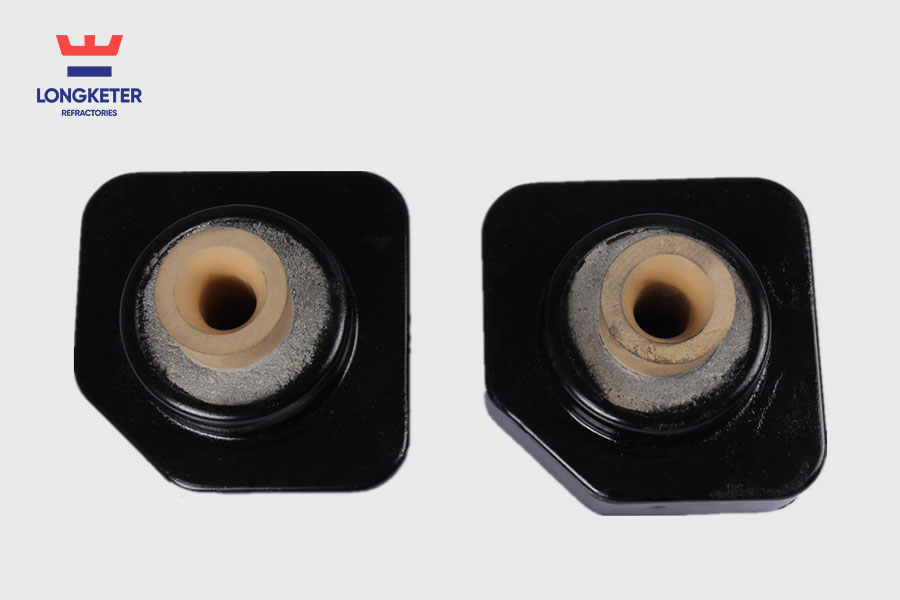

Tundish metering nozzle is a composite nozzle for reasons of economy. The composite nozzle uses an insert and pressed outer body without cement jointing. This method of manufacture provides a reliable system with no risk of steel leakage between the insert and outer body.

It was manufactured by both cast process of fine grained alumina method or press process.

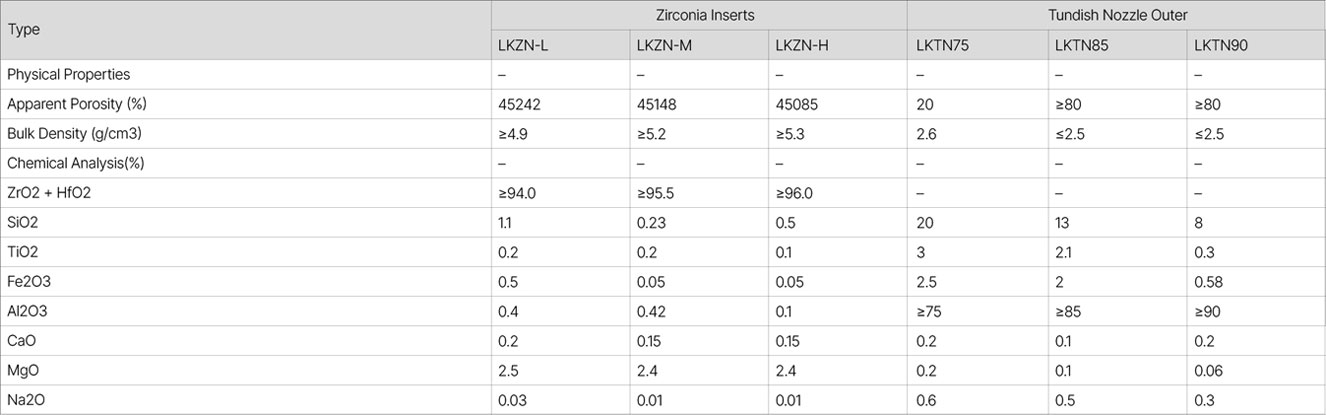

From Tundish to Copper Mould tubes, there are function refractories such like tundish metering nozzles, tundish exchangeable nozzles (Quick-replace nozzle), Monolithic stopper, Submerged Entry Nozzles/Submerged Entry Shroud etc. Tundish nozzles are generally alumina carbon type with zirconia inserts. They are shaped under high pressure hydraulic press. Submerged entry nozzles and monolithic stoppers are generally shaped with isostatic press machine, with zirconia material.

Function refractories are