Monoblock Stopper

Monoblock Stopper (MBS) is an isostatically pressed refractory which is a critical element in the Continuous Casting of Steel where it is used to control the flow of steel from the “Tundish to Mould”.

The stopper nose design helps to achieve desired metallurgical needs by controlling mould level fluctuation, preventing vortex formation and reduce inclusions during steel casting.

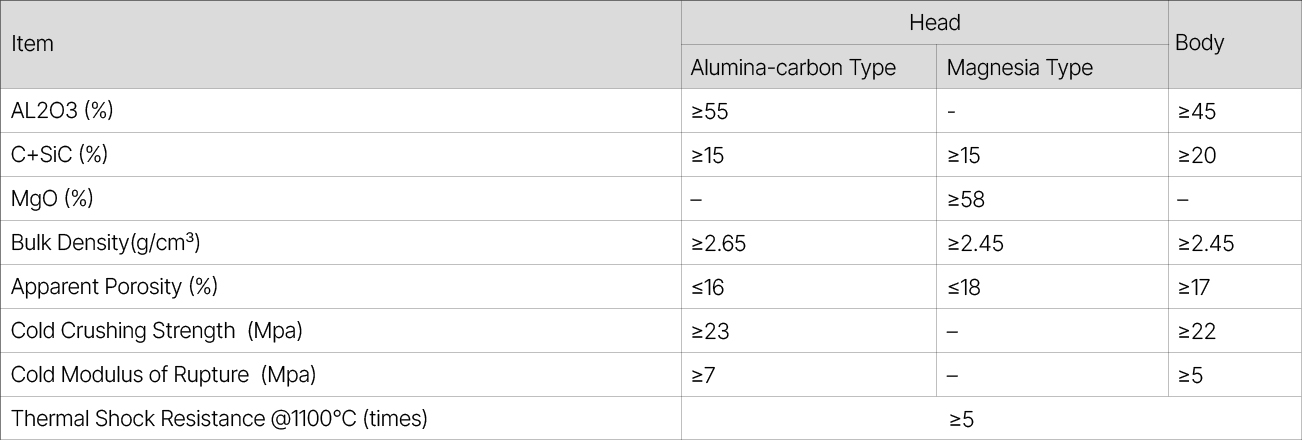

Our monoblock stoppers have several material types such like Alumina-Carbon, Alumina-Zirconia-Carbon, Alumina-Magnesia-Carbon.