Stability of tundish is important factor of stable and qualified steel production, result to pursuit of service life improvement.Among the reasons which cause short service life of tundish, steel clogging between exchangeable nozzles becomes common limitation.

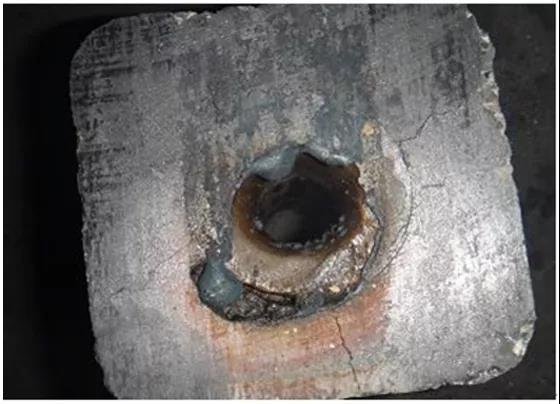

The original reason of steel clogging between nozzles is extra large cracks between plates(Generally crack dimension should be within 0.3 mm), or severe pit corrosion damage(shown as below picture). We conclude most important factors which result in steel clogging.

1.Corrosion of material: This happens to all refractories. Generally tundish metering nozzles or exchangeable nozzles are made from Al2O3-C material, with zirconia inserts,help to improve corrosion resistance. During the usage, impurities (MnO2, SiO2,MgO etc.)inside the molten steel will react with ZrO2, result in lower melting points materials and is washed away by molten steel. As a result the diameter of inserts is expanded. Tundish nozzles are Long Keter’s superior products with advanced producing technology. We also develop and produce anti-swirling nozzles, with better corrosion and erosion resistance, so as to reduce steel clogging problems.

2.Operation: During operation in field, the nozzles should be fired to over 1200 ℃ before applying, so as to reducing thermal cracks because of thermal shock inside the nozzles.

3.Monolithic mechanism : Cracks between upper and lower nozzles should be within 0.3 mm. The upper and lower nozzles are tighten by active slide spring system. Maintenance to springs must be really strict, to assure the free height of nozzles is consistent, and balance pressure is added to different sides of nozzles.

4.Besides,special types of steel, high pressure oxygen blowing or deoxydation treatment, and manual factors when replace nozzles all influence service life.

Tundish nozzles are our superior and main products. According to our rich experience of producing and researching, advice is offered:

1.Assure stable sliding mechanism; assure clean and tidy sliding stroke;keep cracks between nozzles within 0.3 mm

2.Reasonable design of nozzle diameters and materials; inspection of surface need to be checked before applying, avoid cracks/damage/uneven surface.

3.Stable and continuous casting, stable steel types, no extra high or low molten steel is cast.

4.Experienced operating workers are requested, avoid accident because of operation.

5.Assured preheating is proceeded before nozzles are applied.

Long Keter dedicated to supply high quality, reliable tundish nozzles, aim to help controlling molten steel accurately. Adopt to systems as below:

Concast - CNM

Danieli - FNC

Interstop - MNC

Krosaki - OTNC

Vesuvius - CNC/SYS120