Zirconia Refractories

Zirconia Inserts

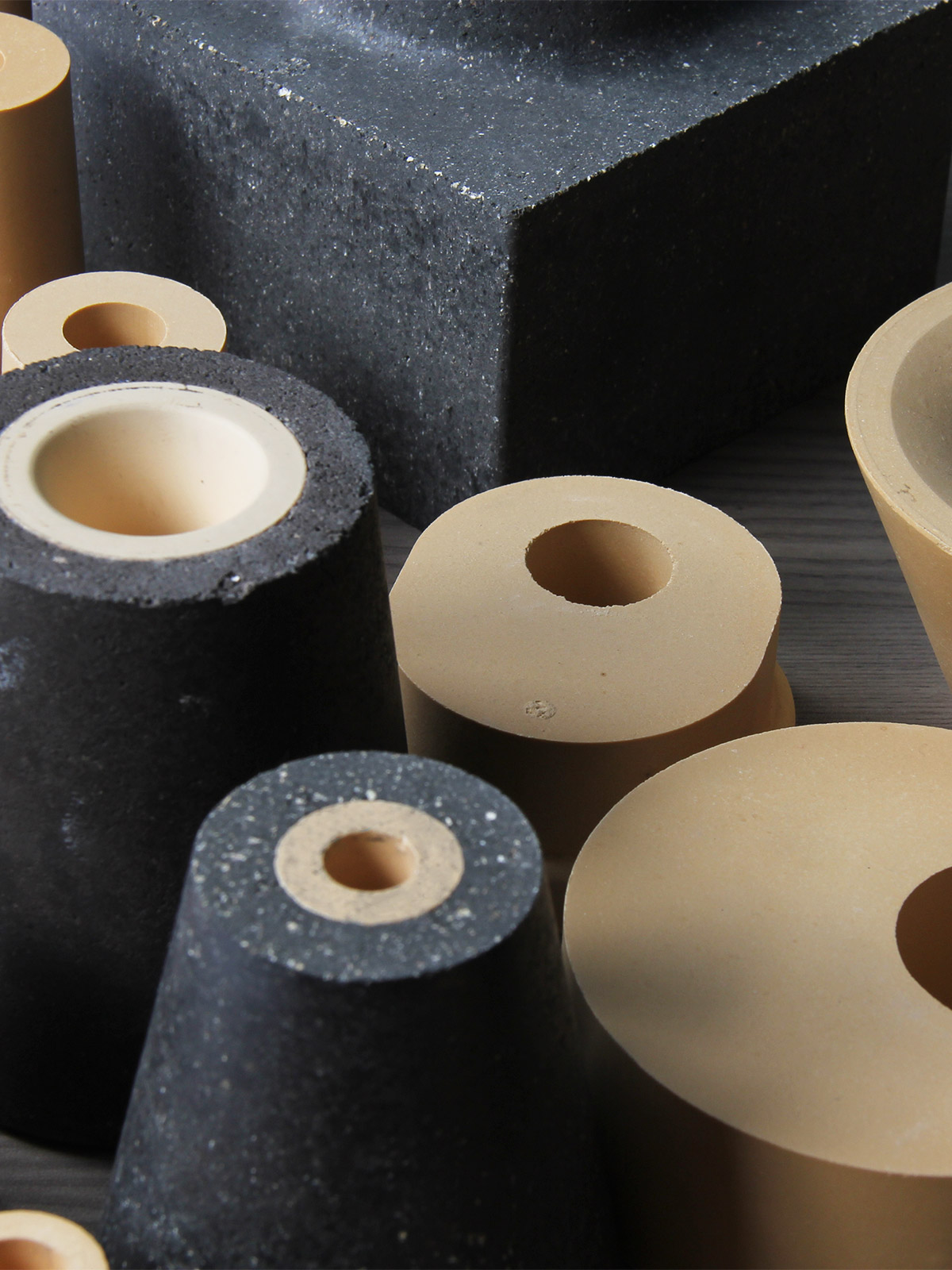

LONG KETER supplying a comprehensive range of zirconia inserts mainly used in continuous casting of steel billets. The inserts, which was known as LKZN series, is magnesia stabilised & high density, can impart excellent erosion resistance even in the most severe casting environments. Consistent casting speeds are achieved and the products have a high resistance to oxygen lancing.

Tundish Metering Nozzles

Upper nozzle(Stationary nozzle)is located within the tundish lining and conveys steel to the controlling exchangeable nozzle, which determines the steel flow. The stationary nozzle must be capable of withstanding long sequence times. Our Upper nozzle that incorporates a ultra-high densityLKZN-M or LKZN-H insert. The insert provides excellent erosion resistance and can provide extended casting sequence times. The lower surface of the stationary nozzle is ground to exacting tolerances to ensure maximum surface contact between the two nozzle components.

Lower Nozzle (EXCHANGABLE) is located within an assembly that is fixed to the bottom of the tundish. The design of the exchangeable nozzle can vary according to the system manufacturer. We supplying a range of zirconia inserts and composite nozzle designs for the exchangeable metering of steel. Zirconia inserts can be supplied for on-site assembly into metallic holding blocks where cementing, grinding, size banding and on site drying are required prior to use.

It was manufactured by both cast process of fine grained alumina method or prese process.

Our nozzles suitable for several nozzle changer systems listed as below

• Concast - CNM

• Danieli - FNC

• Interstop - MNC

• Krosaki – OTNC

• Vesuvius – CNC/SYS120

Sliding Gate Plate

LONG KETER supplying a range of high density zirconia plate inserts, which are used within sliding gate plate applications. Zirconia Sliding Gate Plate Inserts are an excellent solution to increasing the life of sliding gate plates. When the plate become worn, the worn material can be removed and a high density Zirconia Plate insert can be cemented/cast in its place, therefore extending the life of the sliding gate plate.Long Keter offers two material grades for sliding gate plate inserts:

Atomising Nozzle

LONG KETER supplying a comprehensive rang of Atomising Nozzle to Powder metallurgy. Powder metallurgy is a cost effective process despite the convoluted manufacturing route of deconstructing the starting material, utilising the atomisation process, and then reconstructing the product in separate forming and heating stages. And then, there are the immiscible mixes with unique properties that couldn’t be made any other way. In the atomisation process, nozzles controlling the flow of molten metal from the crucible whilst being bombarded with a high pressure jet of air, inert gas or water. A principle feature of all the nozzles is their close dimensional accuracy, which promotes stable flow characteristics under the most arduous conditions.